The world we live in has been invaded by digitalization since the first electronic chips appeared, and the development of computing power and software has made it even more dramatic. Every day we see more and more smart devices from smartwatches to smart home appliances that help you do the shopping, among other things.

This digitalization has opened the door to what is called the Internet of Things (IoT), where physical systems communicate and coordinate with one and another and with humans through the cloud. Of course, companies in different industries such as high tech, automotive, medical, consumer electronics, among others, cannot afford to stay behind in this digital transformation process.

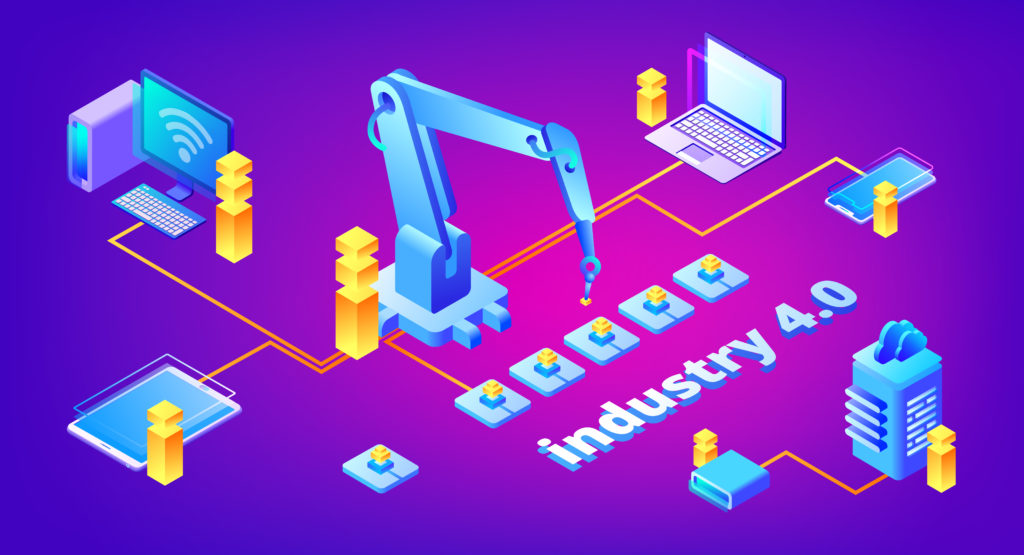

Digital transformation and Industry 4.0

Digital transformation in the industry is the core of the new industrial revolution, “Industry 4.0”. The idea is to make manufacturing processes smarter by having digital systems monitoring physical processes in the factory and decentralizing decision-making processes.

One of the main benefits companies are seeking by applying the digital transformation and entering the Industry 4.0 is to cover the most repetitive tasks and those requiring less critical thinking, so their human resources can be leveraged in a better way for more challenging tasks, especially when emotional intelligence is required.

Where does 3D Printing stand in this digital transformation?

Considering the nature of traditional manufacturing, which is based on centralized mass production, 3D printing can make a big difference for companies trying to move into industry 4.0.

Together with the IIoT or Industrial Internet of Things, Big Data and other technological developments, 3D printing, also known as additive manufacturing, can be considered part of a complex framework for industry 4.0. Moreover, if we consider the benefits that additive manufacturing can provide to industries such as automotive, consumer electronics and medical, there is no doubt that 3D printing fits into industry 4.0 perfectly. Some of these benefits include, but are not limited to:

• Higher prototyping speeds: with the development of 3D printing technologies and materials, companies can have a prototype in minutes, making it easier to test different designs in short periods of time.

• Higher customization: thanks to the speed of current 3D printers, and the fact that only one machine is needed for the whole manufacturing process and materials are cheaper, mass customization is possible. This is an aspect that had been lost in many industries due to the utilization of mass production in order to reduce costs, and it is of great importance for the medical industry to manufacture prosthetics and other very personal products.

• Outsourced and onsite manufacturing: while many big companies may find 3D printing an affordable investment to have their own products, tools or spare parts manufactured onsite, smaller companies and even individuals may find some limitations. However, 3D printing service providers can make it more affordable for those requiring a more “on-demand” alternative to cover the needs of specific projects.

What about supply chains?

Another important aspect of the new industrial revolution is supply chains. With increased environmental awareness and the need for efficiency in their processes, supply chains are trying to reduce the need for transport of their goods, among other aspects that require improvements. As products could be manufactured anywhere where there is a printer and material available while using the same 3D CAD model, large facilities, long transport routes, and complex supply chains will not be necessary.

As mentioned before, 3D printing fits into industry 4.0 perfectly and could be the disruption many industries have been looking for in this new industrial revolution.